A cleanroom is defined in ISO standard 14644 as “a room in which the concentration of airborne particles is controlled, and which is constructed and used in a way to reduce the introduction, generation, and retention of particles inside the space, and in which related parameters, like temperature, humidity and pressure, are controlled, monitored and maintained as obligatory.”

Cleanroom is the pivotal zone in a pharmaceutical segment mandated for environmental monitoring programme as per cGMP/USP/Pharma. A cleanroom is premeditated to retain everything from dust, to airborne organisms, or vaporised particles, away from it, and subsequently from any kind of product that is being handled inside it.

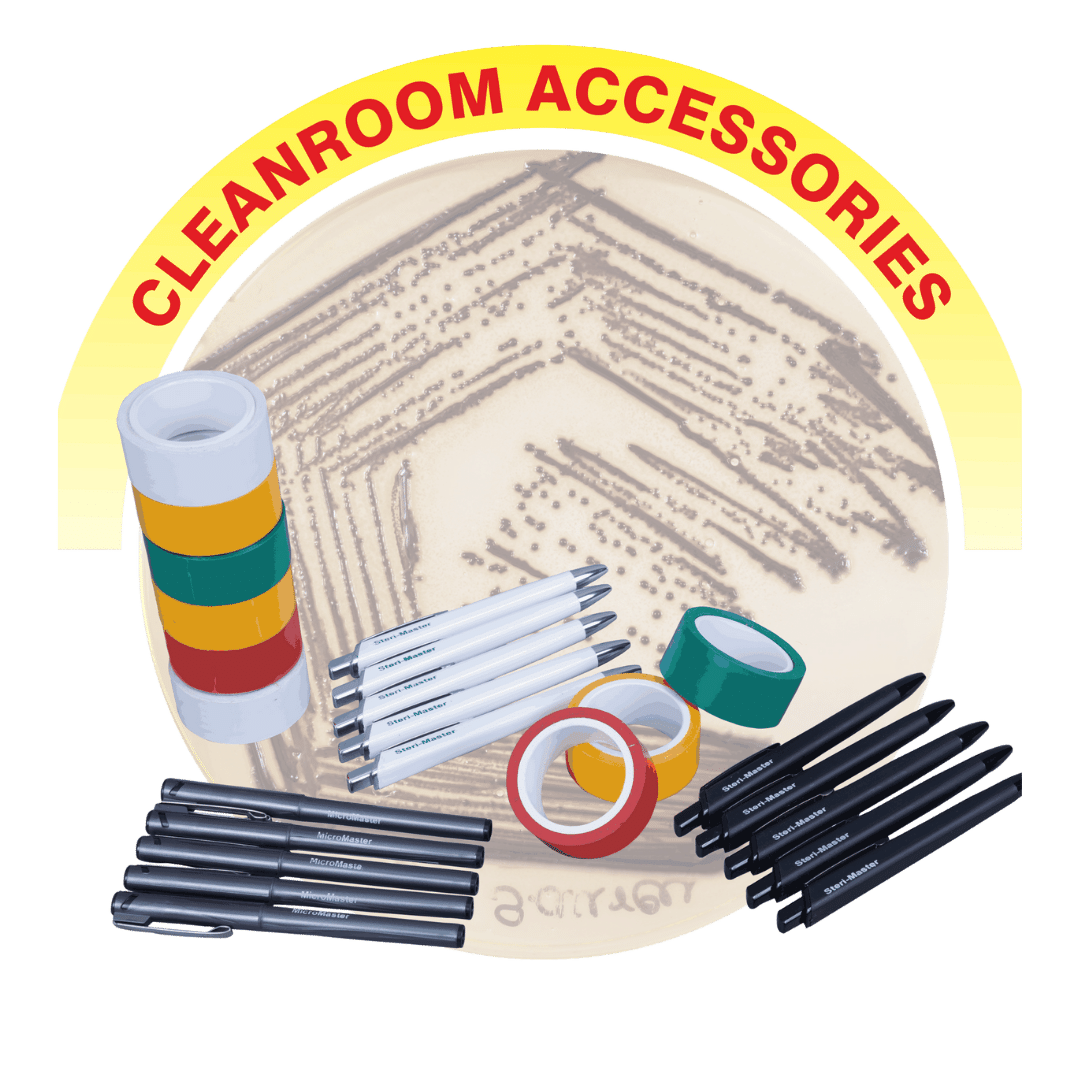

Micromaster Laboratory is pioneer in one-stop solution for all your cleanroom requirements. We have expanded our breadth of operations to provide a wide product range of cleanroom accessories that includes cleanroom tapes, cleanroom location markers, cleanroom markers (gamma irradiated), cleanroom papers, cleanroom petri plates, weighing boats, cleanroom reagent bottles (autoclavable), cleanroom sampling bottles (autoclavable), spray bottles, wash bottles, sterile disposable spoons, maser disposable bags, sterile transport swabs (swab with tube), and much more.